3D design practices are changing the way WisDOT delivers projects by providing better, more complete design information for roadway construction. The main benefits include:

-

Improving design concepts. Additional detail can help to identify design issues during the design process. This creates potential for fewer change orders, costs and delays.

-

Creating additional value. 3D design serves as the foundation of more advanced modeling processes, creating opportunities for future implementations such as visualization modeling and clash detection.

-

Enhancing productivity. Contractors can import a better, more complete design concept into software to improve planning capabilities pre-bid, thus increasing efficiency and construction operation post-bid.

Design Benefits

-

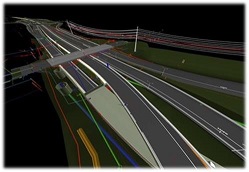

Well-defined detail. Modern 3D design practices use GPS, photogrammetric and LiDAR survey technology to build 3D representations of existing conditions and provide more information about drainage, pavement elevation or pavement slope. The 3D design deliveries are a more detailed representation of the design concept than traditional 2D deliverables alone.

-

Automatic feedback. Dynamic relationships within a Civil 3D designed project allow for the reflection of changes throughout the design concept. Changing one aspect of the design will immediately change all aspects. This cuts down on time and helps streamline analysis of project alternatives.

-

Enhanced project communication. 3D models better enable visualization of project concepts with project stakeholders. Visualization models are especially effective in communicating project concepts with people who do not have a technical background, and are not familiar with standard engineering drawings.

Construction Benefits

WisDOT provides 3D design model information to road construction contractors before they bid on projects, benefitting contractors’ project planning efforts as well as construction operations.

-

Site reconnaissance. This early research makes contractor site visits more efficient and productive. Contractors also can assess options for borrow and waste sites near the project more efficiently, and can estimate volume potential of those sites with less effort.

-

Efficient planning. Contractors can import model information into software tools and more easily verify earthwork volumes and volume distribution throughout the project. This benefits planning while reducing uncertainties and risk.

-

Automated Machine Guidance. 3D design information streamlines the development of Automated Machine Guidance construction models, and helps ensure construction models are consistent with the project design.

-

Construction Staking. 3D design information creates efficiencies in construction staking operations, saving time in plan interpretation and translation into survey systems.

- Improved Communication. Enhanced visualization assists greatly in communicating with nearby property owners about various needs and actions of a construction project, and facilitates improved communications between engineering and contractor staff.

Building on the Technology

In 2010 WisDOT implemented Civil 3D as its roadway design software, enabling 3D workflows for all types of roadway design efforts. After 4 years of piloting the sharing of 3D design information with construction contractors, WisDOT implemented 3D design delivery requirements in 2014. 3D roadway design practices are an example of how WisDOT uses technology to improve project delivery.

3D design information is both an advancement as well as a seed to grow other improvements and efficiencies. For example, the technology helps streamline the development of Automated Machine Guidance Construction models. It also helps to create other efficiencies in construction staking operations, which saves time in plan interpretation and translation into survey systems.

WisDOT Civil 3D projects

Several WisDOT projects have delivered design models to construction over the past few years.

- In 2010, four pilot projects incorporated 3D design models. These projects ran along USH 10 and three of the contractors used the models pre-bid directly. Since these initial pilots, several projects throughout Wisconsin have participated in WisDOT’s pilot program to share 3D Design Models.

- In 2014, WisDOT required designers to provide contractors with 3D design models, pre-bid, for most earthwork projects.

- In 2017, WisDOT embarked on its first stringless paving project which relies on the combination of 3D modeling and high precision Automated Machine Guidance systems.

The

Federal Highway Administration encourages use of 3D technology to create efficiency and cost savings throughout the improvement process.

As more WisDOT projects use 3D Design, WisDOT will develop multiple classifications of design model deliverables that are tailored to the specific needs of different types of roadway construction process. This will allow continued benefits of model-based workflows throughout the entire project lifecycle, and ensure the appropriate amount of effort is applied in the design process. WisDOT will also expand modeling practices into visualization modeling, allowing more utilization of 3D design work to more effectively communicate project concepts and improve public involvement experiences.